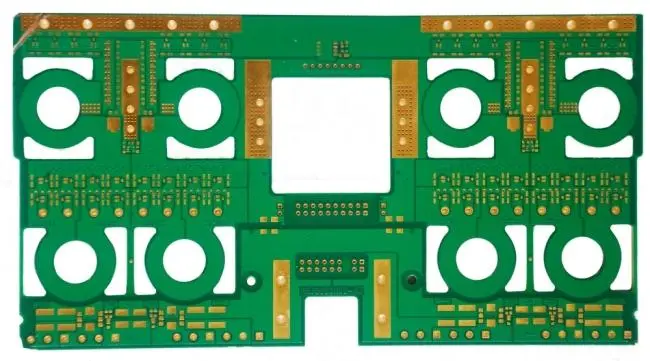

The first is the innovation of PCB productsand MARKets. The earliest PCB product was a single panel, with only one layer of conductor on the insulating board, and the line width was measured in millimeters. It was commercially applied to semiconductor (transistor) radios. Later, with the advent of televisions, computers, etc., PCB products have been innovated. Double sided boards and multilayer boards have emerged. There are two or more layers of conductors on the insulation board, and the circuit width has gradually decreased. In order to adapt to the miniaturization and lightweight development of electronIC equipment, flexible PCB and rigid flex PCB have emerged.

The manufacturing process of PCB resin plug hole includes drilling, electroplating, plug hole, baking, and grinding. After drilling, the hole is plated, then the hole is filLED with resin for baking, and finally the resin is ground flat. Since the resin after grinding does not contain copper, it needs to be coated with another layer of copper to turn it into PAD. These processes are done before the original PCB drilling process, that is, the hole to be plugged is treated first, and then other holes are drilled, and the original normal manufacturing process is followed.

If the plug hole is not plugged properly, when there are bubbles in the hole, because the bubbles are easy to absorb moisture, the plate may burst when passing through the tin furnace. However, if there are bubbles in the hole during the plug hole process, the bubbles will extrude the resin during baking, resulting in the situation that one side of the hole is depressed while the other side is protruding. At this time, the defective products can be detected, and the plate with bubbles is not likely to burst, because the main reason for bursting is moisture, Therefore, if the boards that have just left the factory or have been baked during loading, generally speaking, they will not cause bursting. High Frequency Circuit Board

The green oil plug hole is SIMple for the entire PCB process flow, and can be operated together with the surface ink in the PCB solder mask dust-free room. Or plug the hole before printing. However, the quality of the plug hole is not as good as that of the resin plug hole. The green oil plug hole will shrink after curing. If customers have requirements for fullness, this method cannot meet the product quality. High frequency circuit board rapid proofing

CB circuit board is a row of gold-plated contacts, which is called "golden finger". Don't underestimate these glittering contacts. If one of them falls off or oxidizes, it may cause some hidden troubles. PCB manufacturers need to strictly test each component for many times. Therefore, it is inevitable to plug and unplug the memory for many times, so they strengthened the "golden finger" part. The PCB part of "Golden Finger" adopts a thick 30mil gold plating layer, which is called "thousands of gold". Dingji Electronics has 15 years of experience in board making, and has been focusing on the production of multilayer PCB boards for many years. With quality assurance and considerate service, it is a very good circuit board processing factory. Dingji High frequency circuit boards

The manufacturing process of the foil clad plate is to impregnate the glass fiber cloth, glass fiber felt, paper and other reinforcement materials with epoxy resin, phenolic resin and other adhesives, dry them to Phase B at an appropriate temperature, and obtain the prepreg materials (hereinafter referred to as the DIP materials). Then, according to the process requirements and copper foil lamination, they are heated and pressurized on a laminator to obtain the required copper clad laminate. High frequency circuit board

1、 Classification of copper clad laminate Copper clad laminate consists of copper foil, reinforcement material and adhesive. Plates are usually classified by reinforcement category and adhesive category or plate characteristics.

1. According to the classification of reinforcement materials, the most commonly used reinforcement materials for copper clad laminate are alkali free (alkali metal oxide content shall not exceed 0.5%) glass fiber products (such as glass cloth and glass felt) or paper (such as wood pulp paper, bleached wood pulp paper, cotton wool paper). Therefore, copper clad laminate can be divided into two categories: glass cloth based and paper based.

2. According to the classification of adhesive types, the adhesives used for the foil clad plate mainly include phenolic, epoxy, polyester, polyimide, polytetrafluoroethylene resin, etc. Therefore, the foil clad plate is also divided into phenolic, epoxy, polyester, polyimide, and polytetrafluoroethylene.

3. According to the characteristics and uses of the base materials, the base materials can be divided into general type and self extinguishing type according to the burning degree of the base materials in the flame and after leaving the ignition source; According to the bending degree of the substrate, it can be divided into rigid and flexible laminates; According to the working temperature and working environment conditions of the substrate, it can be divided into heat resistant, radiation resistant, high-frequency foil clad plates, etc. In addition, there are also laminates used in special occasions, such as prefabricated inner laminates, metal based laminates, and copper foil, nickel foil, silver foil, aluminum foil, Kang copper foil, beryllium copper foil laminates according to the type of foil.

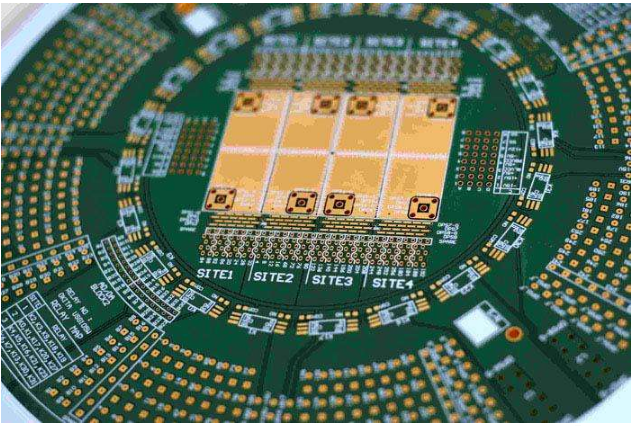

In order to make electronic communication technology develop at a higher speed. High quality high-speed transmission. Many communication equipment now begin to use high-frequency printed multilayer PCB circuit boards. The materials of multilayer high-frequency circuit boards have excellent electrical functions and good chEMIcal stability, mainly including the following four points:

1. It has the characteristics of SMAll signal transmission loss, short transmission delay time and small signal transmission distortion.

2. It has excellent dielectric properties (mainly including low relative dielectric constant Dk and low dielectric loss factor Df). Moreover, this dielectric property (Dk, Df) can still maintain its stability under the environmental changes of frequency, humidity and temperature.

3. High precision control with characteristic impedance (Zo).

4. It has excellent heat resistance (Tg), processing formability and adaptability.

Based on the above characteristics, high-frequency boards are widely used in wireless antennas, base station receiving antennas, power amplifiers, components (splitters, combiners, filters), radar systems, navigation systems and other communication equipment.

Multilayer high-frequency circuit board, based on cost saving, improving bending strength, electromagnetic interference control and other factors, often appears in the form of composite plate, which is called high-frequency composite plate. There are many kinds of high frequency mixed compression materials selected and designed for lamination and combination, which are too numerous to enumerate. Through research and development, Mingyi Electronics has experimentally produced a multilayer high-frequency circuit board, which uses high-frequency materials RO4350B/RO4450B and FR4 to mix and compress