1、 Part of power panel output power control circuit

The most important part of the output power board of the power board is the part of the output power control circuit. In this case, you should first understand the characteristICs of the power circuit of the part of the output power that is distributed. In the power supply, the key part of the output power power circuit is divided into di/dt power circuit and dv/dt power circuit. The routes of these two power circuits are different under the condition of reasonable PCB layout and wiring.

The di/dt power circuit has a large change of electric flow per unit time, so it is of paramount importance that the total loop area of all power circuits should be as SMAll as possible in the case of PCB wiring for these power circuits. It is better that the wiring of one loop is overlapped at different layers, so that the total loop area of the power circuit is the least, and the impact caused by itself can be coupLED off.

The focus of dv/dt power circuit is completely different. Because the working voltage of this type of power circuit changes greatly in a unit time, it is very easy to have an impact on the outside. Therefore, the copper sheet of this type of power circuit should not be too wide under the condition of wiring. The overall width of the copper sheet should be as small as possible under the condition of considering the load bearing electric flow, the overlapping area of different layers should be as small as possible, and the wiring of sensitive data signals should be avoided as far as possible.

2、 Part of the power board drive

The total area of all driver control loops shall be considered first for some lines of the driver, which shall be as small as possible. Interference signals shall be eliminated, and the lines shall be as close to the part of the driver as possible. For drivers of output power components such as MOS tubes, it is important to note that the wiring of G-pole and D-pole does not have to run in parallel. In most cases, the power circuit of a part of the D-pole of MOS tubes is the power circuit of dv/dt, and the G-pole is the optocoupler circuit. If the parallel plane runs well, the driver data signal is very easy to be affected, thus causing incorrect MOS operation.

3、 Power board sampling data signal

Sampling data signals such as some operating voltage sampling and current sampling are also particularly important in the output power panel. Because whether the power panel is accurately related to the control terminal immediately, all such sampled data signals should bypass other data signals as much as possible. If there is a standard, such sampled data signals can be sampled by differential signals, In addition, a detailed ground plan can be provided for the corresponding PCB wiring area.

4、 Solution to power board grounding

Not to mention the necessity of land, no matter what kind of board it is, the solution to land is very critical.

The ground in the output power board is relatively complex. In many cases, part of the output power goes to the ground with large electrical flow, and some of the ground with small electrical flow is common to the ground. Therefore, the solution to this problem is very critical. In my work experience, the key to solving this problem is to select an appropriate point connection point. Because the PCB design scheme of each power supply is different, Therefore, the selection of this point injection node is different. In the small output power photovoltaic inverter, a ground pin of the BUS capacitor is generally selected. In the soft starter, I usually lead a relatively thick wire from the ground pin of a capacitor in the large current flow to the ground pin of the capacitor at the input end of the power switch, Later, these small current ground plans led from this ground pin to the rear of the power switch power supply naturally have some other places, such as the ground of the active crystal oscillator, the ground of the sampling, etc. Each enterprise has different solution standards and routes, and there are more materials for the online ground solutions.

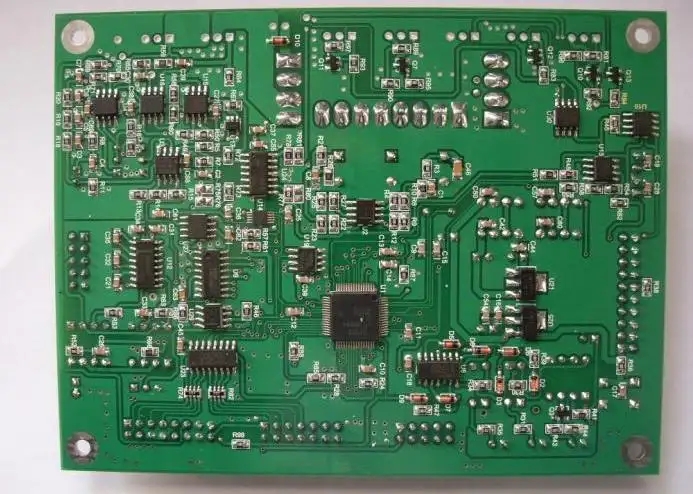

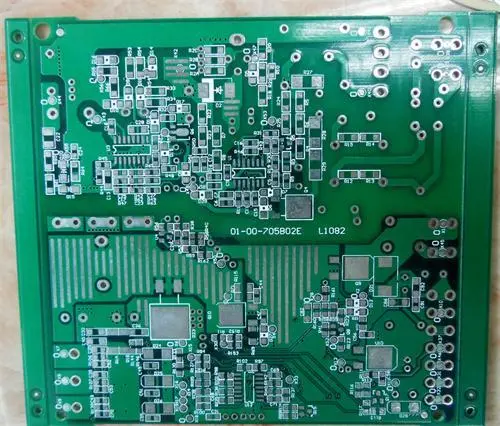

Power supply board

5、 Electrical safety of power panel

Electrical safety is essential in the design scheme of power supply products. The electrical safety policies, regulations and provisions of power boards for different countries and regions are also different, and the environmental pollution level and average elevation of application scenarios are more harmful to the spacing of electrical safety. All of these elements must be clarified at the beginning of the design scheme, If there are electrical safety technical engineers, they can be asked to find out the distance between the more technical and professional creepage and electrical clearance. In the case of PCBLayout, people should pay attention to the location of these metal material components on the PCB, such as the fuse tube, where the middle of the metal materials on both sides is non-metallic materials. If there is no base, the metal materials on both sides of the fuse tube will touch the PCB, The surface wiring around all the safety pipes shall avoid the metal material area.

6、 Power board heat pipe heat dissipation

For these system software with large output power, heat pipe heat dissipation is also particularly important. This general situation needs to be well coordinated with the structure. Before the design scheme, it is necessary to master the heat pipe heat dissipation method of the overall structure, which is of course refrigeration, air cooling or water cooling. Air cooling is divided into air inlet and hair dryer, which are more harmful to the reasonable layout.

7、 Power board EMC

It is mainly that the total width of PCB wiring with part of the output power should not change suddenly as much as possible. If it is necessary to turn, the turning area should also be as calm as possible without sudden changes. Sometimes there are also large electric flow, small current, and some of the sampled data signals. Although some of them use the same Internet, they do not need to use the same control loop for their own wiring. They should be separated, Each control circuit is better.