Lecture on PCB board evaluation skills: understanding the factors needing attention

About the artICle PCB technology, challenges faced by modern PCB design engineers, this article will explain PCB design, when a PCB designer is a PCB design tool. The following are some possible PCB designers must consider and influence their decision:

PCB board

1. Product Features

1.1 Basic functions covering basic requirements, including:

1) Interaction between schematic and PCB layout

2) Routing functions such as automatic fan out routing, push-pull, and routing capabilities based on design rule constraints

3) DRC checker

1.2 The ability to upgrade product functionality as the company engages in a more complex design

1) HDI (High Density Interconnect) interface

2) Flexible design

3) Embed passive components

4) Radio Frequency (RF) Design

5) Automatic script generation

6) Topological layout and routing

7) Manufacturability (DFF), Testability (DFT), Manufacturability (DFM), etc

1.3 additional products can perform analog analog, digital analog, analog digital mixed signal analog, high-speed signal analog, and RF SIMulation

1.4 Have a central component library that is easy to create and manage

2. Can help you design products with efficiency and technology in a short period of time

3. Among the above factors, price should be a secondary consideration, and more attention should be paid to the rate of return on investment!

There are many factors to consider PCB board evaluation The type of development tool designers are looking for depends on the complexity of their design work As the system becomes more complex, the physical routing and placement control of power components become so extensive that critical paths must be constrained in the design process However, too many design constraints limit the flexibility of design Designers must have a good understanding of their designs and rules so that they know when to use them The design definition is closely integrated with constraint editing In constraint editing, designers can define physical and electrical constraints Power constraints will drive the simulator for pre - and post placement analysis for network verification Check the design definition carefully. It is also connected to the FPGA/PCB board The purpose of FPGA/PCB board integration is to provide bidirectional integration, data management, and integration between FPGA and PCB boards Enter the same physical implementation constraint rules during the layout phase as during the design definition This reduces the chance of errors from files to layouts And even input and output interface group (IO_Bank) exchange all need to return to the design definition stage for updating

2.1 HDI

The increase in semiconductor complexity and the total number of logic gates has required integrated circuits with more pins and finer pin pitches. It is common to design more than 2000 pins on a BGA device with a spacing of 1mm, let alone 296 pins on a device with a pitch of 0.65mm Faster rise times and Signal Integrity (SI) requirements require a higher number of power and ground pins The need for density interconnect (HDI) technology. HDI is an interconnection technology developed to meet the above requirements Microvias and ultra-thin dielectrics, thin traces and SMAll line spacing are key features of HDI technology

2.2 RF Design

For RF design, the RF circuit shall be directly designed into the system schematic diagram and system board layout, rather than being used in a separate environment for subsequent conversion All analogies and tuning still require the optimization capability provided by the RF simulation environment, but the analog environment accepts more raw data than the "real" design Therefore, the differences between data models and the resulting design transformation problems will disappear First, designers can directly interact between system design and RF simulation; Second, if designers are conducting large-scale or quite complex RF design, they may want to assign circuit analogy tasks to multiple computing platforms running in parallel, or they may want to reduce the analog time by sending each circuit in multiple designs to their own simulator

2.3 Advanced Packaging

The increasing functional complexity of modern products requires a corresponding increase in the number of passive components, which is mainly reflected in low power consumption and high frequency applications Although the packaging of passive surface mount devices has shrunk significantly in the past few years, the results are still the same when trying to reach the final density Printed component technology has enabLED the transition from multi chip assemblies (MCMs) and hybrid assemblies to today's SiP and PCB board directly embedded with passive components Assembly technology used in the conversion process For example, the inclusion of a layer of persistent materials in a layered structure and the use of series termination resistors directly under the microball grid array (uBGA) package has greatly improved circuit performance Embedded passive components can now be designed with high accuracy, eliminating the need for additional processing steps for laser cleaning welds In wireless components, the trend is to add integration directly in the substrate

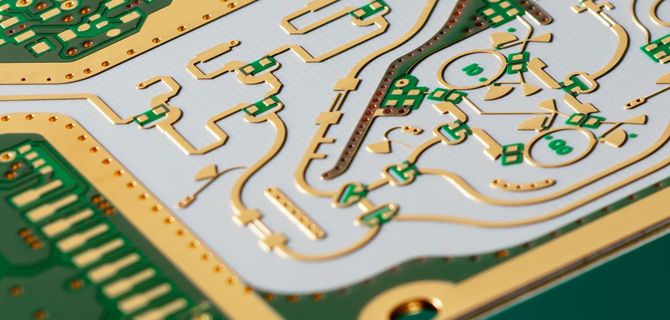

2.4 Rigid-flex PCB

In order to design a rigid flex PCB, all factors affecting the assembly process must be considered Designers cannot simply design rigid and Flexible PCBs like rigid PCBs, as if rigid and flexible PCBs are just another rigid PCB They must manage the bending areas of the design to ensure that the design points do not break and flake the conductor due to stresses on the curved surface There are also many mechanical factors to consider, such as bending radius, dielectric thickness and type, metal plate weight, copper plating, total circuit thickness, number of layers, and number of bends Understand rigid and flexible design and determine whether your product allows you to create rigid and flexible design

2.5 Signal Integrity Planning

In recent years, new technologies related to the parallel bus structure and differential pair structure of serial to parallel conversion or serial interconnection are progressing continuously Typical design problems encountered in the design of parallel bus and series parallel conversion The limitation of parallel bus design is the change of system timing, such as clock offset and propagation delay Due to the clock offset in the bus width, it is still difficult to design timing constraints Adding a new clock frequency will only make the problem worse On the other hand, differential pair architecture uses swappable point-to-point connections for serial communication at the hardware level Typically, it transmits data through a one-way serial "channel", which can be stacked in 1 -, 2 -, 4 -, 8 -, 16 -, and 32 width configurations Each channel carries one byte of data. This bus can handle 8-256 byte data width. By using some form of error detection technology, data integrity can be maintained However, due to the high data rate, there are other design problems High frequency clock recovery becomes the burden of the system, because the clock needs to be quickly locked to the input data flow and reduce jitter between all cycles to improve the anti jitter performance of the circuit power noise also brings additional problems to designers This noise adds the possibility of severe jitter, which makes it more difficult to open your eyes Another challenge is to reduce common mode noise and solve the problems caused by ic package loss effects, PCB boards, cables, and connectors

2.6 Utility of Design Kits

Design kits such as USB, DDR/DDR2, PCI-X, PCI Express and RocketIO will undoubtedly be of great help to designers entering new technologies The design toolkit outlines the technology, details, and the difficulties designers will face, followed by an analogy and how to create routing constraints It provides descriptive files along with the program, which provides designers with the opportunity to master advanced new technologies It may be easy to find a tool that can handle the layout of PCB; However, it is important to obtain a tool that not only meets the layout but also can solve your urgent needs