pcb factory: operation specifICation of reflow welder and 5 precautions

In the reflow welding process, if you want to get a good welding effect, it has a lot to do with the operating specifications of the reflow welding machine. Next, I will introduce the operating specifications and precautions of the reflow welding machine to help you have a deeper understanding of the use of the reflow welding machine. 1、 Operation specification of reflow welding machine 1. Before starting up, check whether there are sundries in the equipment, and clean it to ensure safety. 2. Turn on the power and turn on the switch. Note: press and hold the switch button for 1-2 seconds and then release it. 3. Open the control software to set the temperature of reflow soldering. Generally, the furnace temperature reaches the set value in 20-30 minutes. 4. Adjust slowly according to the size of the circuit board

In the reflow welding process, if you want to get a good welding effect, it has a lot to do with the operating specifications of the reflow welding machine. Next, I will introduce the operating specifications and precautions of the reflow welding machine to help you have a deeper understanding of the use of the reflow welding machine.

Reflow soldering operation specification

1、 Operation specification of reflow welder

1. Before starting the machine, check whether there are sundries in the equipment and clean it to ensure safety.

2. Turn on the power and turn on the switch. Note: press and hold the switch button for 1-2 seconds and then release it.

3. Open the control software to set the temperature of reflow soldering. Generally, the furnace temperature reaches the set value in 20-30 minutes.

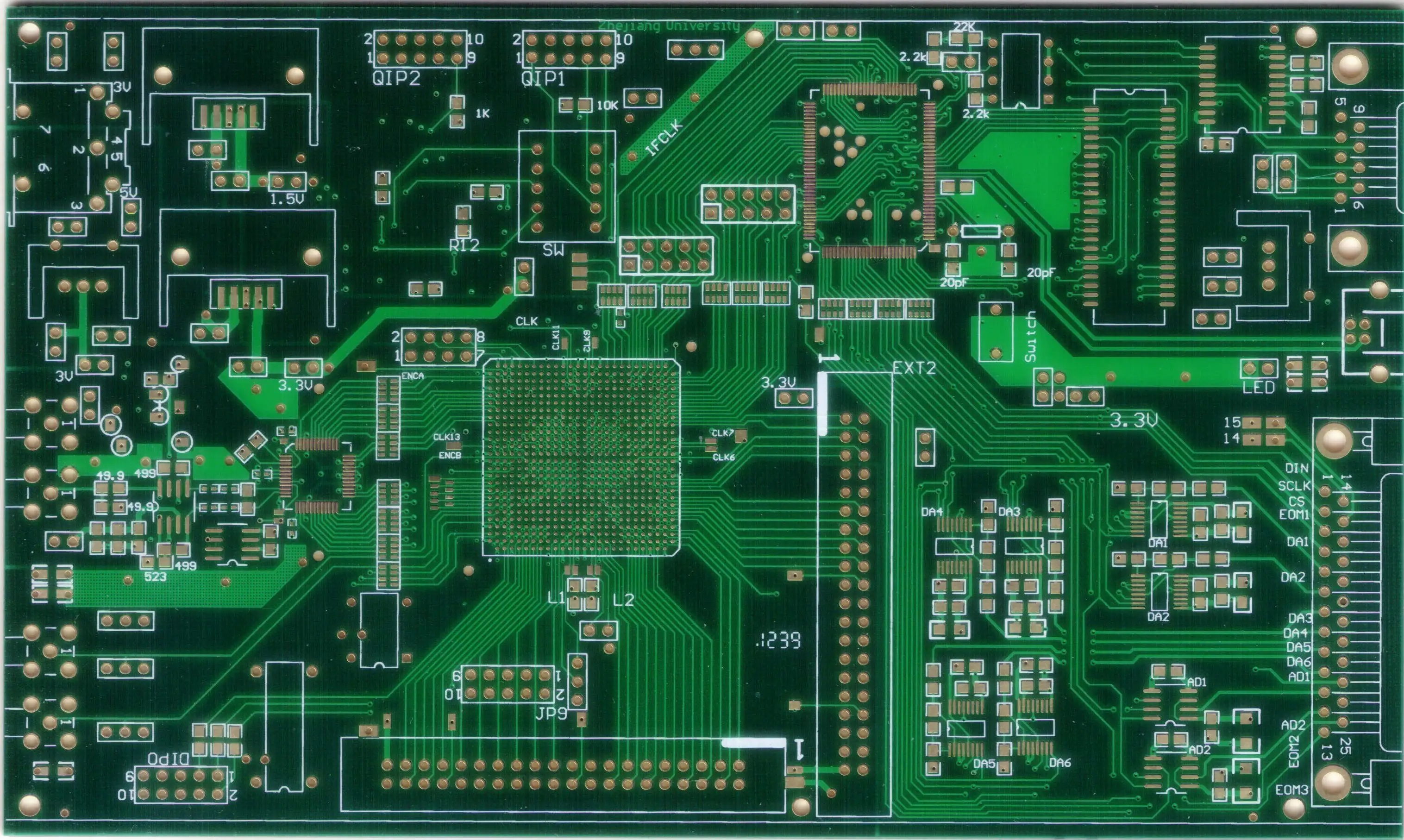

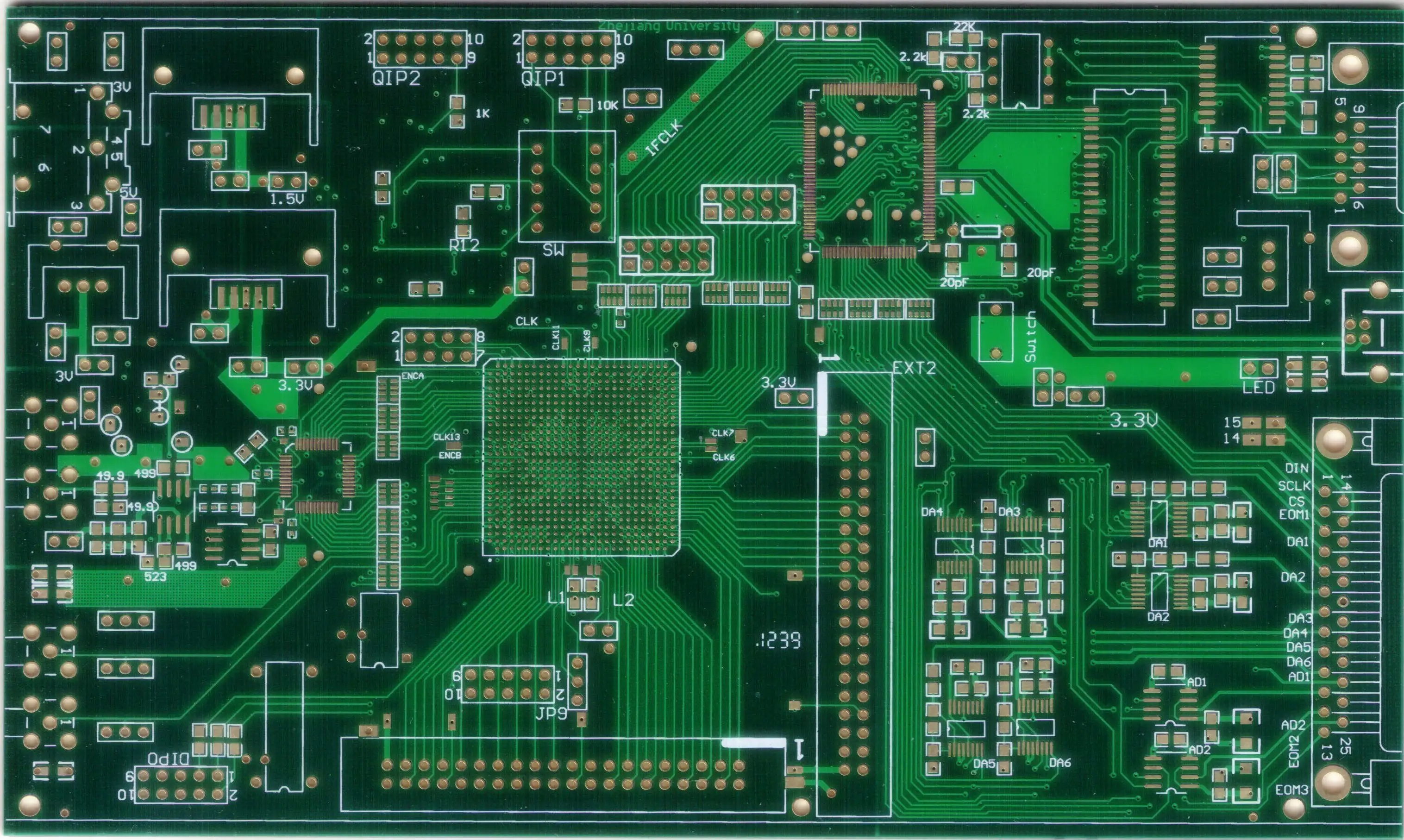

4. Adjust the width of the guide rail slowly according to the size of the circuit board. The machine must be stable without tilting or instability. It is strictly prohibited to put other items into the furnace cavity except the circuit board and temperature measuring equipment during operation.

5. Check whether the four emergency switches at the end of the inlet and outlet spring up and remove the four emergency switch protection rings.

6. Check that the power supply of the exhaust fan is correct and then connect the power supply.

7. Turn on the temperature zone switches in sequence. When the temperature rises to the set temperature, start to pass the PCB. Pay attention to the direction of passing the PCB, and ensure that the distance between two consecutive boards of the conveyor belt is not less than 10mm.

8. Measuring temperature: insert the sensors into the receiving socket of the tester in turn, turn on the power switch of the tester, place the tester in the reflow soldering and reflow soldering with the old PCB, take out the temperature data recorded by the tester in the reflow soldering process, which is the original data of the temperature curve of the reflow soldering machine.

9. Do not cut off the power supply before the reflow soldering is shut down. The system will automatically enter the cooling operation mode. The hot air motor will continue to work for 10-15 minutes. After that, the hot air motor will stop working. At this time, the heat source can be turned off.

2、 5 Precautions

1. Reflow welding operators shall be trained before taking the post, and non operators shall not operate the machine.

2. During the operation of the machine, head, hand and other body parts shall not be put into the machine.

3. Ventilation shall be ensured during welding to prevent air pollution. Operators shall wear work clothes and masks.

4. In case of sudden power failure or motor failure, push the central push rod of the manual handle inward, and shake the handle clockwise to quickly shake out the circuit board that has entered the furnace. During normal operation, the central push rod shall be pulLED out so that the handle does not rotate with the rotating shaft.

5. In case of any accident, please press the emergency button to stop the machine.

Reflow soldering process, as a key process in SMT, plays an increasingly important role in SMT process. To obtain good welding effect, it is necessary to have skilled operators and correct operation specifications.

The Circuit board manufacturer and the circuit board designer will explain the operation specifications of the reflow welder and 5 precautions.