Circuit board manufacturer: how to identify the quality of SMT steel mesh?

The Circuit board manufacturer and circuit board designer explain how to identify the quality of SMT steel mesh

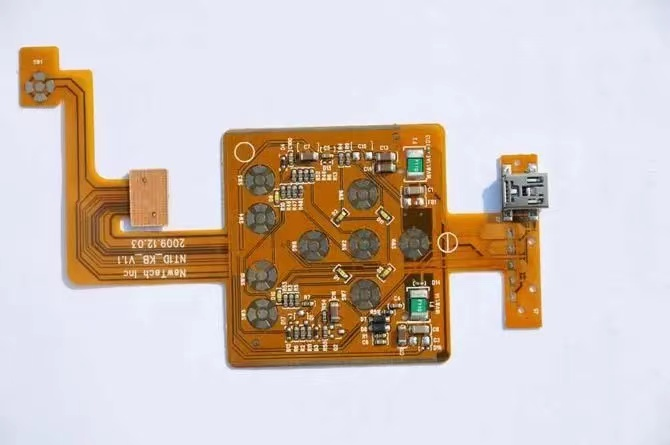

SMT stencil is a special SMT mold, whICh is mainly used to help solder paste accurately transfer to PCB pads through the stencil port. The determination of SMT stencil is the prerequisite for solder paste printing, which has a very important impact on the later operation of SMT. With the increasingly sophisticated electronIC components, the quality requirements for SMT stencil are becoming higher and higher, so how to identify the quality of SMT stencil? To judge whether a steel mesh is good or bad, it mainly depends on whether the fabricated steel mesh meets our specification requirements, mainly from the following aspects. 1. Check whether the steel mesh is made of stainless steel. 2、

SMT stencil is a special SMT mold, which is mainly used to help solder paste accurately transfer to PCB pads through the stencil port. The determination of SMT stencil is the prerequisite for solder paste printing, which has a very important impact on the later operation of SMT. With the increasingly sophisticated electronic components, the quality requirements for SMT stencil are becoming higher and higher, so how to identify the quality of SMT stencil?

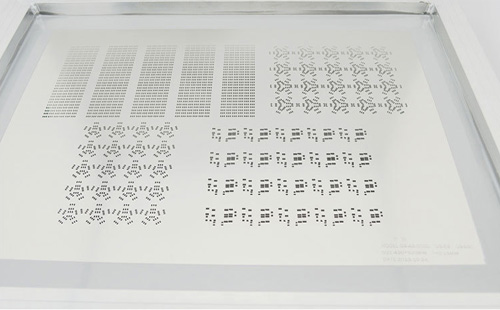

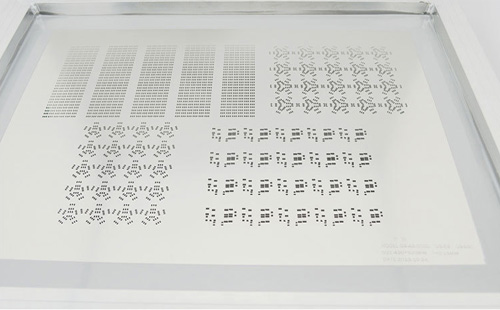

To judge whether a steel mesh is good or bad, it mainly depends on whether the fabricated steel mesh meets our specification requirements, mainly from the following aspects.

1. Check whether the steel mesh is made of stainless steel.

2. For the width depth ratio/area ratio of steel mesh design, the generally accepted design guideline for acceptable solder paste release is that the width depth ratio is greater than 1.5 and the area ratio is greater than 0.66. When the length is greater than five times the width, the width depth ratio should be considered first.

3. Whether the shape of the opening meets the requirements, and whether the appearance quality of the mesh has obvious defects.

4. Check whether the hole wall is smooth and free of burrs, and focus on the processing quality of narrow pitch IC pin openings.

Practice is the only criterion to test the truth. To verify the quality of a SMT steel mesh, enterprises can operate the steel mesh once according to the specific situation to check whether the steel mesh meets the requirements, but this will increase the cost. Generally, this method is used only when the steel mesh is too dense.

The circuit board manufacturer and circuit board designer explain how to identify the quality of SMT steel mesh.