DetaiLED explanation of 3 aspects to be vigilant in PCB procurement

PCB procurement plays an important role in the entire electronIC product production supply chain management. PCB carries the electrical connection of all electronIC components, and its quality concerns the stability and long-term reliability of electronic products. For PCB purchasers, the following three aspects need to be closely watched to ensure that PCB is procured in line with the project quality and the best economic interests.

1. Position the performance requirements of your electronic products for PCB boards

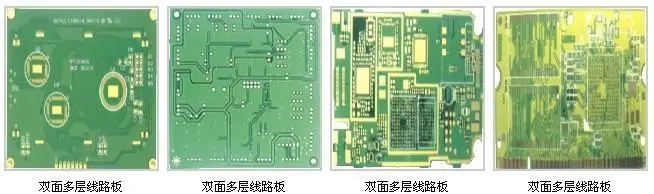

First of all, it is necessary to analyze the MARKet positioning of the company's products, and select high-quality products for middle and high-end products; Low end products pursue price targets, which is the most basic concept. However, it is very important for purchasers to grasp the R&D cycle of electronic products. In the proofing stage, the general efficiency is paramount, the price is secondary, and the quality is in the middle. Therefore, purchasing personnel are required to seek PCB factories that can provide rapid proofing, such as Jialichuang, which is popular in the market at present. However, in the stage of SMAll batch and large batch production, PCB procurement needs to be controlled in terms of quality and delivery time. Purchasers need to be very familiar with the design structure, accuracy requirements, line width and line spacing, number of layers, copper thickness and other important indicators of the product pcb board. For some electronic product PCB boards that require special processes, they are positioned to look for high-quality PCB manufacturers.

2. Select appropriate PCB manufacturers for procurement

People are always the best business card of the company, because equipment can be bought, but equipment and plant are not omnipotent. Therefore, it is particularly important for purchasers to "inspect" the sales managers and even the bosses of PCB manufacturers. A conscientious and responsible manager with customer service philosophy will lead a good production team and provide high-quality PCB products. Especially under the prEMIse of highly developed PCB equipment, human management has become the embodiment of the competitiveness of PCB manufacturers. Secondly, it is necessary to carefully review the Pcb factory's production capacity, process capacity, customer distribution, peak and low season cycle and other indicators, so that the purchasing staff can know well.

3. Basic knowledge of PCB inspection

Placing an order and receiving goods is not the end of the purchasing staff. The purchasing manager also needs to know more about PCB inspection, so that he can distinguish the corresponding quality level when auditing the factory and inspecting the goods. PCB manufacturers and PCB designers explain three aspects of PCB procurement that need to be vigilant.