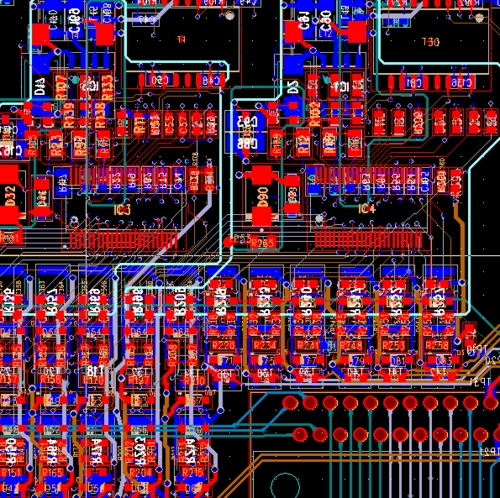

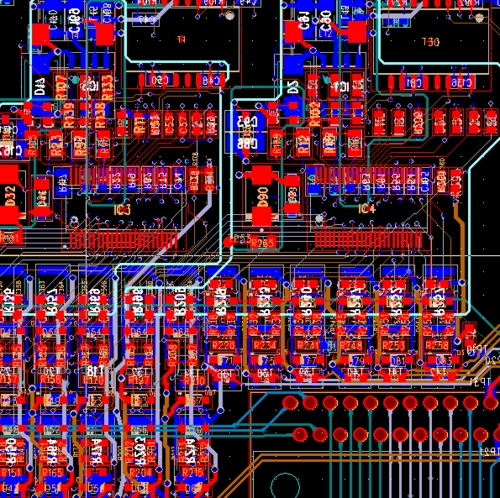

Have you ever seen the PCB (printed circuit board) of radio or computer? Is there any interconnected electronIC components? No, Then, this is a circuit board containing pads and circuits, whICh can be electrically connected together at different points, or more specifically, connect components and connectors to each other. The circuit board allows signals and power to be easily imported through physical devices. With the help of solder, the components on the surface are electronically interconnected.

Solder is a metal suitable for use as a strong adhesive on PCB components. You can find PCB in precision radar, pager, buzzer and even computer software. Because of their different uses, PCBs have different designs, shapes and sizes. For example, printed circuit boards for aircraft have more complex designs that have been invented to meet the growing capabilities of aircraft. It is not easy to design PCB for aviation.

Aviation printed circuit board

For beginners, their must be more powerful, which requires the implementation of specific layout and design techniques. Making circuit boards for aircraft is a difficult and time-consuming task. Pay special attention to the thermal management of PCB, and consider the special design and layout technology of high-frequency RF components. Therefore, in order to manufacture printed circuit boards for aerOSPace equipment, basIC design and layout must be considered to make them more superior.

This means that designers must define the correct board material, specify accurate drill charts, maintain neat assembly considerations, retain stacking recommendations for layout, add additional bedding for mechanical dimensions and holes, use the correct termination methods, and perform pre layout SIMulations. The designer of the aircraft circuit board must also verify the impedance calculation, shield the signal, separate the ground plane and the power supply, and then maintain the correct aspect ratio.

Reasons for special PCB design and PCB layout

Other requirements that PCB designers should consider include that PCB design should have additional current buffer pads and also use the correct milling cutter specification components. This is indeed a demanding process. MIL-SPEC components are mainly used in aviation PCB design because their tolerances are very SMAll. For recording, additional current buffers are used to enhance the current in the circuit.

Due to the sensitive nature of the components found in the aircraft, printed circuit board applications are made with circuits that properly handle three amps. Why? Aircraft circuit boards require only a maximum load of two amperes. Therefore, the three amp circuit can handle important applications in PCB used in aircraft. If there is an abnormal or too high peak, the extra margin can easily handle everything. All of these designs and layouts play a key role in making PCB in the aviation industry more robust and efficient.