PCB outgoing SMT processing and PCBA OEM

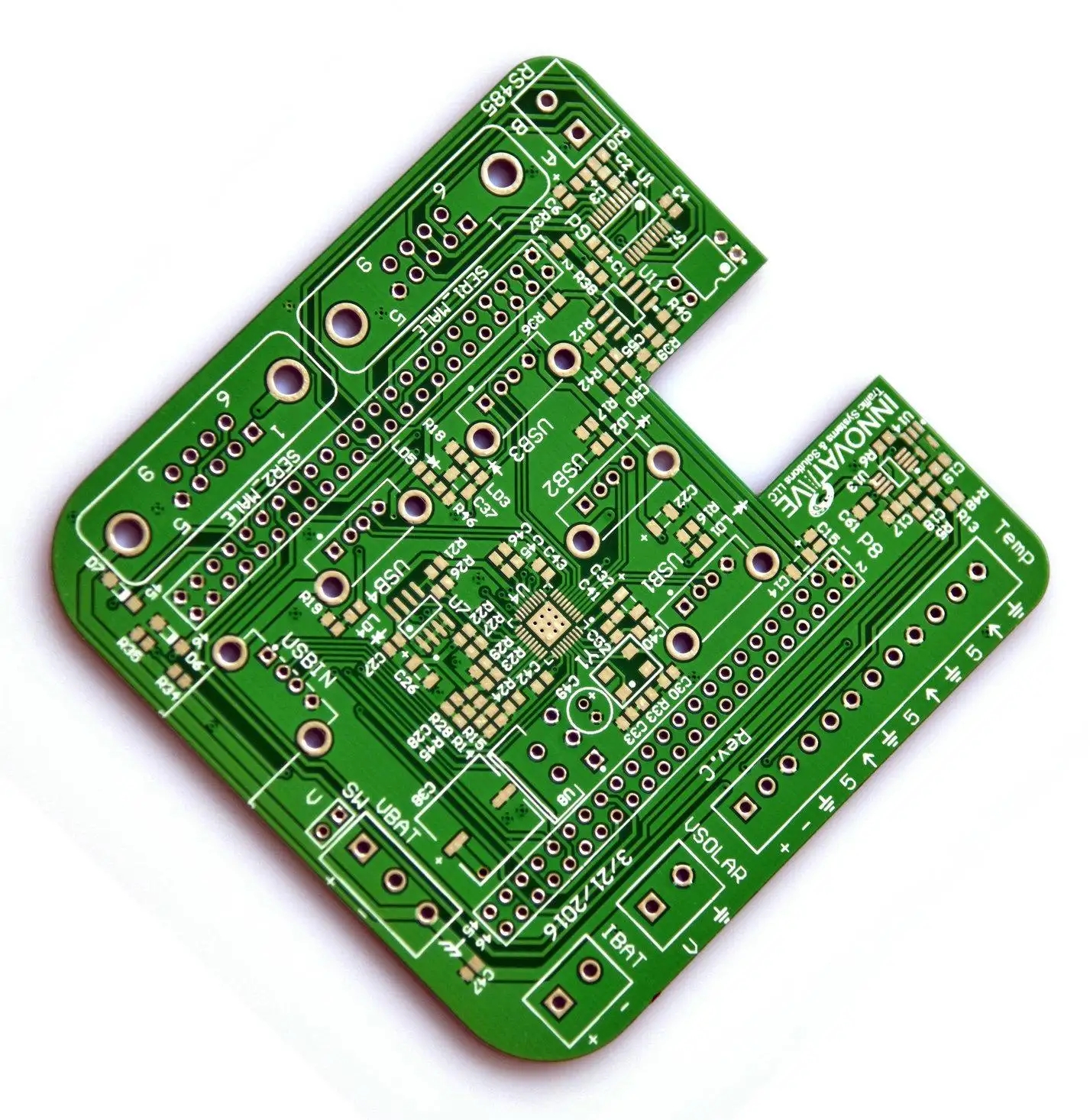

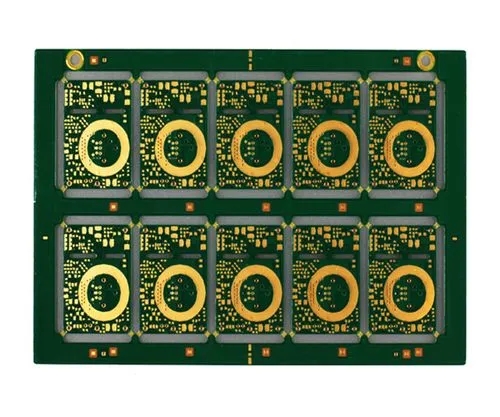

PCBA processing is to connect various electronIC components on PCB board through surface mount (SMT), plug-in (DIP) and other electronIC assemblies. PCBA process flow mainly includes SMT, AOI, DIP, FCT testing and other processes. Due to the size difference of electronic components, there will be different processes and requirements in assembly and insertion. The assembly density of PCBA is relatively high, and the SMAll size and light weight of electronic products also have certain changes and requirements in mounting. The reliability, seismic resistance and excellent weldability of the products have high requirements for the hardware and software facilities of PCBA processing.

Many electronic product manufacturers find professional PCB factories to make circuit boards, SMT manufacturers to make patches, and then come back to assemble, test and sell their own, which is almost the usual operation mode in the past. However, is such operation really the best solution? Is the cost of PCBA OEM compared with the enterprise's own situation? In the future, the competition of enterprises tends to be infinitely enlarged at a certain point, rather than the whole process control in the whole value chain, which is almost an irreversible trend.

In view of this, it is absolutely necessary for an enterprise to carefully calculate the purchase cost, inventory cost, cost of purchasing warehouse management personnel, error cost, etc. of raw materials, and then compare the quotation with that of PCBA. It will be surprising to find that the overall cost of PCBA manufacturing has decreased and the risk has decreased. It seems that the price has risen on the surface, but the actual cost has dropped sharply when professional people are entrusted to do professional things.

PCB outsourcing SMT processing is less and less used by electronic product R&D companies. They are beginning to look for suitable PCBA overall manufacturing solution providers, and they just need to be good judges and arrange a small number of personnel for production tracking management. Many people will question the question about the capital flow, claiming that PCBA OEM and material replacement processing generally requires about 70% of the advance payment. In fact, this is not different from PCB outsourcing SMT processing, because many upstream materials such as IC are also purchased with cash, and there are not many suppliers who can make monthly settlement.

Today is not the past. The electronic manufacturing industry is very mature. The average profit margin of the processing industry is saturated, and there is no sudden profit. Enterprises begin to compete for service capabilities. PCBA OEM can effectively replace PCB outgoing SMT processing mode, reduce the comprehensive cost of personnel, warehousing, logistics and after-sales, and gradually become the favorite of electronic product manufacturers focusing on core R&D and sales, and begin to consciously transform to PCBA mode.